Spent coffee grounds (SCG) are one type of organic waste that makes up a significant proportion of the organic waste going to landfills and has the potential to produce 21 times more methane gas emissions that contribute to global warming compared to carbon dioxide. Therefore, it becomes imperative to look for a recycling solution to transform this waste into a valuable resource. In this regard, the concrete industry has the potential to contribute significantly to increasing the recycling rate of this waste material.

Due to the high content of organic materials, direct use of this substance in structural concrete is unsuitable. Therefore, researchers of RMIT University conducted a study on pyrolysing this waste at different temperatures (350 and 500 ◦C) to identify its suitability in improving the physicochemical and mechanical properties of concrete. They used the raw and pyrolysed forms of SCG as a replacement of fine aggregates (FA; sand) at 5, 10, 15 and 20% volume replacement levels.

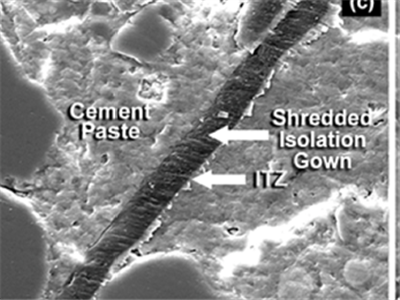

The results show that the compressive strength of concrete decreases with an increase in the percentage of SCG. However, the pyrolysing the SCG at 350 ◦C (350CBC) led to a significant improvement in its material properties, which resulted in a 29.3% enhancement in the compressive strength of the composite concrete blended with coffee biochar. On the other hand, the compressive strength results for concrete containing 500CBC indicate that higher porosity and increased micro-cracking in 500CBC concrete are most likely weakening the cement microstructure, resulting in the reduction in the compressive-strength results that decrease with the increase in 500CBC content.

In conclusion, from the analysis of the SCG، 350CBC and 500CBC results, it can be concluded that 350CBC15 (maximum sand replacement level of 15%) provides the best-performing concrete mix that provides the highest improvement in the concrete strength results.

https://doi.org/10.1016/j.jclepro.2023.138205